Traditional magnetic hooks have long been a go-to for lightweight storage solutions, offering a simple and damage-free way to hang items on steel surfaces.

From kitchen utensils to small tools, their ease of use and portability have made them popular in homes, offices, and workshops. However, these hooks have historically fallen short when tasked with holding heavier items.

Their limited magnetic field strength and tendency to slip or fail on thinner steel surfaces meant they weren't considered viable options for more demanding storage needs.

That all changes with the advent of Gator Magnetics, which leverages cutting-edge magnetic technology to redefine what magnetic hooks can do.

Designed to securely hold up to 45 lbs of shear force*—even on thinner steel surfaces—these innovative solutions bring the power of magnets into the realm of heavy-duty storage, making them a true game-changer for professionals and DIYers alike.

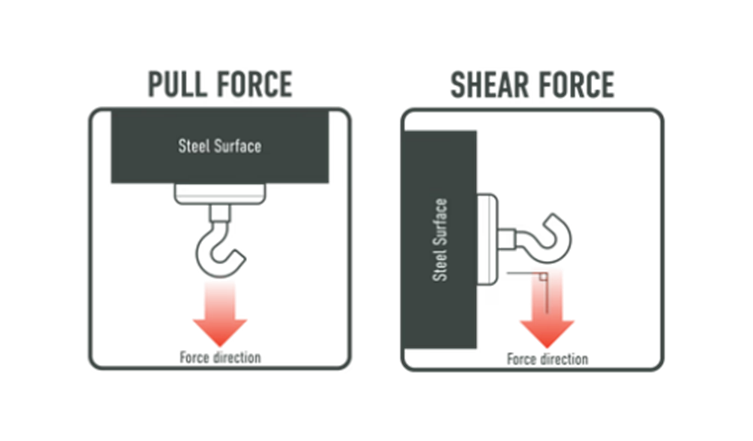

How the Magnetic Industry Measures Weight Capacity

The magnetic industry's pull force measurement refers to the force required to remove a magnet directly (vertically) from a steel plate, usually a minimum of ½” thick.

This value is typically determined by using controlled conditions, including a thick, flat steel plate to ensure maximum contact with the magnet.

The formula for calculating pull force generally incorporates magnetic strength, the surface area of contact, and material properties of the steel.

However, pull force doesn't account for shear force, which measures the resistance to sliding and can vary significantly based on factors like friction, coatings, or surface irregularities.

For example, a traditional magnet's shear force on a vertical surface is usually only 15-30% of its pull force due to factors like gravity and surface friction.

This is why a traditional magnet may claim it holds 25 lbs, but in reality, that means it will hold 3.75 lbs - 7.5 lbs of shear force.

Additionally, variables such as steel thickness, air gaps (e.g., coatings or uneven surfaces), and steel composition can greatly reduce the actual holding capacity of a magnet compared to its pull force measurement in ideal conditions

Introducing Shear Force, What is it and Why Is It Critical To Hook Performance?

When evaluating magnetic hooks, it’s crucial to distinguish between pull force (the magnet's strength when lifted directly away from the surface) and shear force (its resistance to sliding downwards), as these factors determine how much weight the hook can truly support in different orientations.

The magnetic industry commonly measures and advertises pull force, which often overstates a hook's practical weight-holding ability, especially for a magnetic hook on a wall application where shear force is the limiting factor. Understanding this distinction ensures a more accurate assessment of a magnetic hook's performance in real-world scenarios.

When Comparing Magnetic Hooks, Pay Attention to the Surface Thickness You Want to Hang Items On.

Steel thickness plays a significant role in how effectively magnetic hooks perform. Different steel surfaces vary widely in thickness, influencing the holding power of magnets.

For instance, a steel cabinet is often constructed with 20-gauge steel (approximately 0.036 inches thick), while toolboxes are typically made from thinner 22-gauge steel (0.03 inches thick). Pole barn walls, designed for lightweight yet durable construction, usually range from 25 to 28-gauge steel (0.017 to 0.014 inches thick).

Meanwhile, the walls of work vans tend to fall in the 18 to 22-gauge range (0.048 to 0.03 inches thick), providing a more robust but still thin surface. By comparison, industrial steel plates, such as 1/2-inch thick steel, are considered 0 gauge and offer the optimal substrate for traditional magnetic solutions.

Traditional neodymium magnets often fail to maintain reliable shear force holding strength of more than 10 lbs. on thin steel surfaces below 1.2mm (16-gauge) thickness, as they cannot fully utilize their magnetic field. This limitation highlights the need for advanced magnetic technologies, like Gator Magnetics' patented Maxel technology, which ensures high performance even on thinner materials, broadening the range of practical applications.

What Makes Gator Magnetics Revolutionary?

Maxel Technology: Redefining Magnetic Strength* and Uses.

The cornerstone of Gator Magnetics’ innovation is Maxel technology, which programs north and south poles onto the same surface of a neodymium magnet. This unique approach maximizes shear force holding power while solving one of the biggest pain points in traditional magnetic hooks: Reduced holding capacity when supporting weight at a 90-degree angle to the floor, especially on thinner steel surfaces.

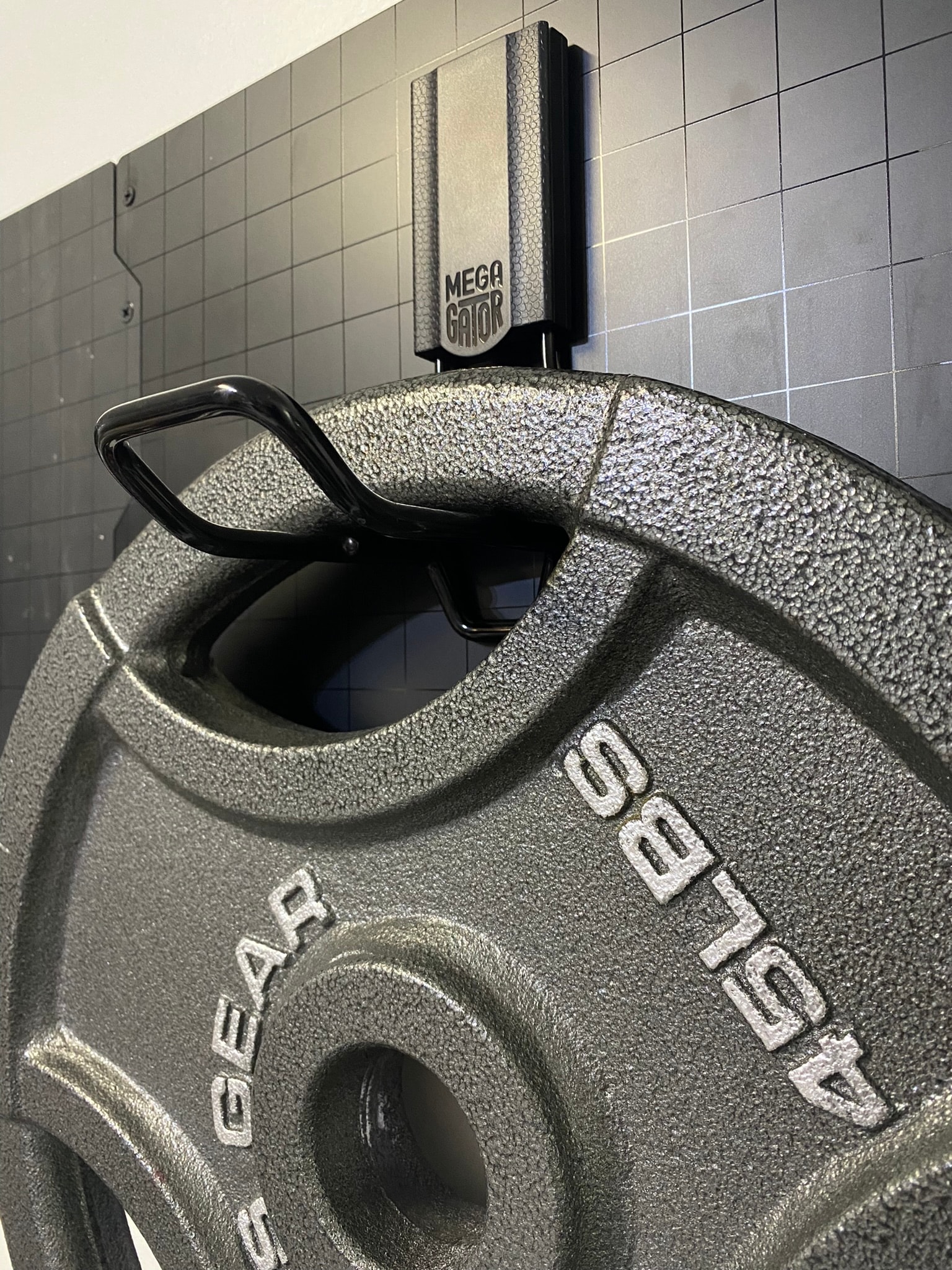

Where others struggle to grip securely on thinner steel surfaces, Gator Magnetics excels, providing unmatched stability for heavy-duty applications. Whether you’re hanging a 25-lb. tool on a 20-gauge steel cabinet or hanging a 35 lb backpack leaf blower on 16 gauge steel, these hooks deliver consistent capacity to hang heavier items on thinner steel surfaces.

Heavy-Duty Capacity for Demanding Applications

With the ability to hold up to 45 lbs. even on thinner steel, Gator Magnetics’ hooks outclass their peers. This makes them a reliable choice for a wide range of uses: from industrial settings like garages and workshops to home spaces like kitchens and laundry rooms.

Their exceptional strength also means they’re perfect for seasonal tasks, such as hanging wreaths on the front steel door during the holidays. Unlike adhesive hooks or nails, which may fail under heavy loads, Gator Magnetics offers a secure, reusable alternative.

Horizontal Placement: Revolutionized by Gator Magnetics

The orientation of magnetic hooks has always been a defining factor in their weight-holding capabilities. Traditionally, vertical placement was critical for maximizing holding strength, as it aligned the load’s weight directly against the magnet’s pull force. Conversely, horizontal placement relied more on friction, which significantly reduced effective weight capacity, making magnets less practical for heavier items in this orientation.

Gator Magnetics changes everything. Thanks to their patented Maxel technology, the limitations of traditional magnets in horizontal placements are now overcome. Now, when you’re using Gator Magnetic hooks horizontally, these magnetic hooks ensure superior adhesion or holding power, even on thinner steel surfaces, something traditional magnets could never achieve reliably. Their enhanced grip and optimized magnetic strength allow for practical, heavy-duty use in horizontal configurations. This versatility eliminates the need to compromise on weight capacity or placement options.

Built for Industrial Strength

With the ability to hold up to 45 lbs. of shear force, Gator Magnetics hooks excel in demanding industrial settings. Their breakthrough technology ensures consistent performance and durability, even in applications where traditional magnets fail. Regular care, such as keeping them clean and dry, and the steel surfaces clean, further enhances their longevity and reliability.

Perfect for the Garage, Home and Small Spaces

At home, Gator Magnetics’ hooks transform organizational challenges into opportunities for smart storage. Their magnetic baskets, for example, are designed to hold up to 35 lbs., offering the perfect solution for clutter-prone areas like workshops, laundry rooms, and kitchens.

Attach them to a refrigerator to store cleaning supplies or use them in a garage to keep tools accessible. These hooks work seamlessly with modern lifestyles, adapting to spaces like lockers, whiteboards, and even washing machines.

Optimized for Travel and Unique Needs

For travelers and cruise-goers, magnetic hooks are indispensable for making the most of limited cabin space. Use them to hang towels, jackets, and accessories without causing permanent damage to the walls. Gator Magnetics’ high-strength hooks excel in these scenarios, keeping everything organized.

The Future of Magnetic Storage

When evaluated, we believe Gator Magnetics’ innovation doesn’t just improve on the existing concept of magnetic hooks; it revolutionizes how we think about storage and organization. Their patented technology empowers users to tackle heavier loads, work with thinner surfaces, and embrace a truly flexible approach to organizing their spaces.

From DIY enthusiasts and industrial professionals to homeowners and travelers, Gator Magnetics offers a solution that adapts to every need. With unmatched strength, versatility, and reliability, these hooks are setting a new standard in the world of storage.

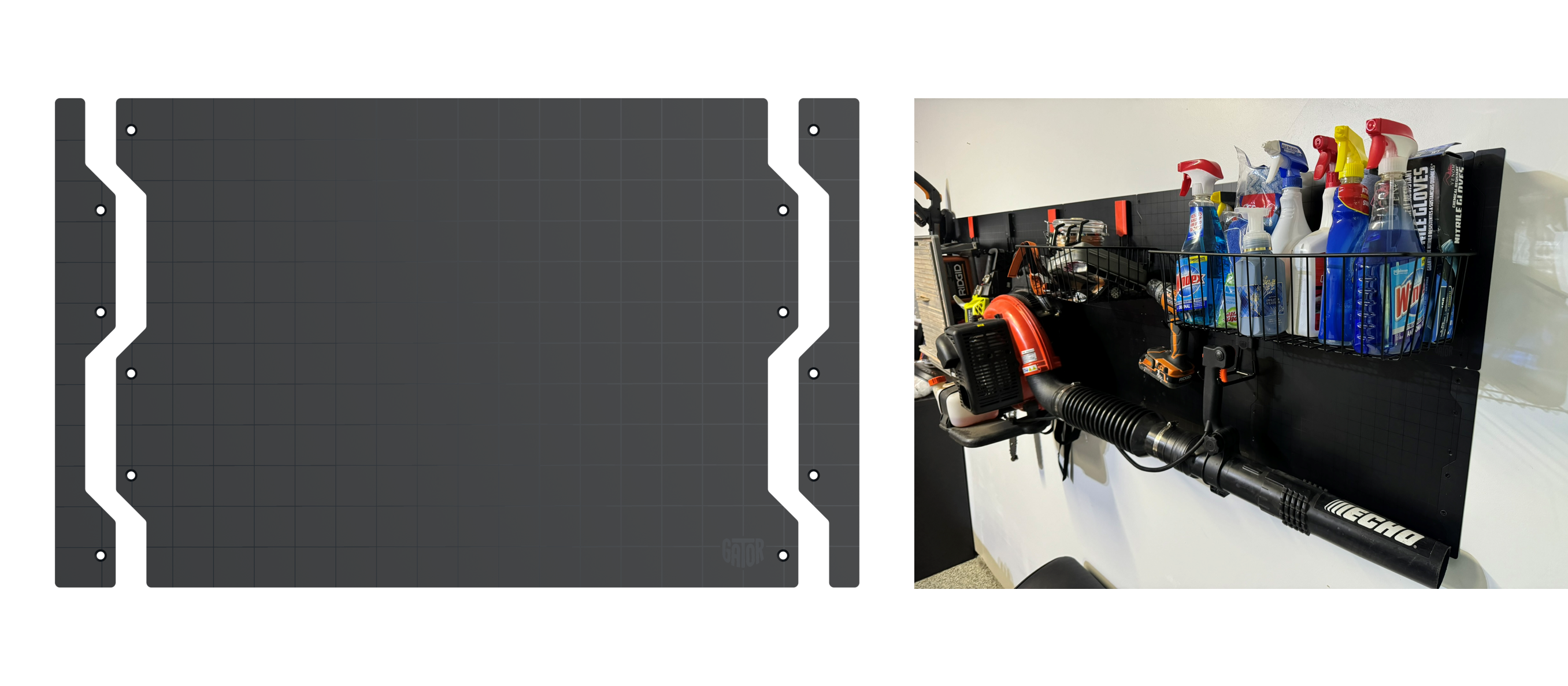

No Steel. No Problem

For those without access to steel surfaces, Gator Magnetics offers a clever solution: the Gator Steel Wall System. This easy-to-install innovation provides a dedicated steel surface, enabling users to fully utilize Gator Magnetics' versatile magnetic storage products. Ideal for garages, sheds, or workspaces, the Steel Wall System ensures that anyone can enjoy the benefits of magnetic organization, regardless of their existing setup. It’s a practical way to bring order and convenience to any space, proving that Gator Magnetics has thought of everything to meet their customers' needs.

The Verdict

Magnetic hooks are a staple for anyone looking to organize their space, but Gator Magnetics elevates the concept to a whole new level. Their patented Maxel technology addresses longstanding challenges while opening doors to applications previously out of reach for traditional magnetic hooks.

Whether you’re looking to organize a workshop, tidy up a kitchen, or make the most of a small space, Gator Magnetics delivers. Their products aren’t just hooks—they’re a smarter, stronger, and more innovative way to keep your life organized.

Embrace the future of magnetic storage.

Frequently Asked Questions

What are magnetic hooks made of?

Traditional magnetic hooks are composed of neodymium rare earth magnets, encased in sturdy materials for durability. Gator Magnetics, however, takes this a step further by using its patented Maxel technology, which programs magnetic poles on the same surface of the neodymium magnet. This unique design delivers unheard of shear force holding power, particularly on thinner steel surfaces, setting Gator Magnetics apart from conventional options.

How much weight can a magnetic hook hold?

While traditional magnetic hooks claim they can hold up to 90 lbs under optimal conditions, their strength is highly dependent on surface thickness and orientation of the steel surface. Gator Magnetics, with its innovative design, consistently delivers superior weight-holding capabilities even on thinner steel, overcoming limitations that hinder traditional hooks.

Can magnetic hooks be used on any surface?

Magnetic hooks work best on ferrous surfaces, such as steel, with their effectiveness varying based on the material's thickness. Unlike traditional hooks, which struggle on thinner surfaces, Gator Magnetics' advanced technology ensures reliable holding power across a wider range of steel surfaces, including thin panels like those on work vans or pole barns.

How can I prevent my magnetic hooks from rusting?

Traditional magnetic hooks should be stored in dry environments to avoid rusting, and rust-resistant finishes or coatings are recommended. Gator Magnetics products are engineered with premium materials and coatings to withstand harsh conditions, further differentiating them from standard magnetic solutions.

Are magnetic hooks suitable for horizontal placement?

Horizontal placement diminishes the weight-holding capacity of traditional magnetic hooks, as it relies on friction rather than direct magnetic force. This is the core of Gator Magnetics technology as it is based on overcoming this limitation by delivering superior shear force resistance, making them more effective. in both horizontal and vertical orientations compared to conventional options.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.