Magnetic storage solutions have revolutionized the way tools and equipment are organized. With innovative technologies like Gator Magnetics, heavy tools can now be stored close at hand, increasing convenience, productivity, and safety. This guide explores the advantages of magnetic storage solutions, contrasts them with traditional systems, and highlights the features of Gator Magnetics' patented products.

Key Takeaways

The ability to store heavy tools close at hand, positioning specific tools for new projects, for different users, and then to store them away is a breakthrough for many.

New, revolutionary magnetic technology is changing the way magnetic hooks work, increasing productivity by allowing users to instantly reposition very strong hooks, keeping the most used tools close at hand whenever they are needed.

These new hooks are easy to move and hold tools substantial shear force weight on almost any metal surface. They can be placed on sheet metal wall surfaces, on the side of toolboxes, on refrigerators/freezers, on appliances – really a surprising number of places that are common in homes, garages, and workshops.

The ability to easily move the hooks with one hand makes it possible to change the position of a tool to its most convenient location when needed or store it out of the way when done.

Advantages of new technology Magnetic Hooks over: (a) permanent or mounted hooks (shelving or “peg systems”); or, (b) other magnetic hooks.

The Problem with Traditional Magnetic Storage:

Many daily-use tools, though manageable when handled directly, become “heavy” when accessed from inconvenient positions. Static organization systems such as shelves, pegboards, and rail systems require significant effort to reconfigure and often lead to inefficient tool placement. Traditional magnetic hooks, while moveable, lack the strength to securely hold heavier tools on thin steel surfaces.

Why a Configurable Tool Storage System Matters

There are 3 principal reasons that a highly configurable tool storage system is important. First there is simply convenience. Second is productivity. Third is the reduction of stress injuries from overreaching for tools.

Convenience. Simplified access to tools makes tasks more enjoyable and encourages repeated use.

Although it may seem obvious, the ability to perform a task with minimal complexity or exertion contributes not only to the pleasure of completing the task, it may also influence a user’s willingness to undertake future tasks. That is, if the task is more enjoyable, it is more likely that someone will take it on again.

Productivity: Easily accessible tools minimize time wasted searching and reaching, improving overall efficiency.

Very few people measure a task by time or effort, they simply work until it's done. Nonetheless, whether or not someone has a measurement applied to completing a task, there is an intuitive sense of whether it was “easy”. And the level of productivity we experience in completing a task greatly affects our sense of satisfaction. The percentage of time required to find the right tool, reach for tools, and the effort it takes to do so, is one of the primary factors in productivity. Tool availability is a primary factor in productivity (see Tradesafe’s article at https://trdsf.com/blogs/news/tool-management-streamlining-efficiency-and-maximizing-productivity?srsltid=AfmBOoqVMzaK7v33HitxaDjXUvcR4XvyTp6sx8Xd8nZ5x_WUxU7E2RPT).

A highly configurable organization system that allows you to put the tools where you want them, and then easily change their position at any time, allows one to “infinitely configure” your work areas. One of the features of the new magnetic hook system is the ability to remove the hooks with one hand, with light force, then move the hook to a new location. This new location may in fact be close to the work, on the side of a toolbox, or any sheet metal near the work. The tool will then be “at hand” in just a second.

Safety: Proper tool placement reduces the risk of injuries caused by overreaching or twisting to access heavy items.

There are many expert opinions and reports on this specific topic, from OSHA, NIOSH, the MIL standards, and the CDC. Related to accessing a tool from a shelf or a hook, their data shows that injuries occur when reaching for a tool. The most common injury would be when extending or reaching with one arm to lift something greater than 5 kg or 11 lbs, especially if your reach requires any “twisting” motion. With that in mind, the best storage solution is the one capable of positioning tools where they are the simplest to reach – and the need to reach tools is changeable, because different tools are needed for different purposes.

The obvious problem is that different tools are needed for different times, projects, or by different people. And therefore, the best storage system is one that allows tools to be positioned dynamically and to accommodate close and easy proximity of specific tools for specific projects. This is a challenge to “static” organization systems (those not easily reconfigured) because they create a need for extended “reaching” to take down a tool or replace it into storage. They also are not capable of simultaneously placing a tool where it is temporarily “stored” so that it is easily accessible as close as possible to where it will be used. An example would be to position a tool on the side of a toolbox temporarily.

Injuries are exacerbated by repeated work and hurried work. So, productivity, and flexible temporary positioning of tools can make a big difference. Also, keep in mind that the weight recommendations for reaching with an extended arm vary from person to person, depending on the hand size, hand strength, arm length & arm strength, and other factors. So, for many people, there are very distinct advantages to tool placement.

Gator Magnetics: A Game-Changer in Tool Storage

Advantages of Gator Magnetics Over Traditional Systems:

Strong Holding Force: Gator hooks provide reliable vertical holding (shear force) for heavy tools, even on thin steel surfaces.

Infinitely Configurable: Hooks can be repositioned with ease, allowing for dynamic storage tailored to specific tasks or users.

Versatility: Unlike fixed shelving or peg systems, Gator hooks can be used on any metal surface, enhancing their utility.

Durable Design: Patented magnetic flux patterns ensure stability and strength, even for the heaviest tools.

Gator Magnetics Helps Increase Productivity

Imagine being able to make a specific tool handy for a specific task, lifting the tool with one hand and removing and reattaching the hook to any metal surface. That is what we call “infinitely configurable”. Imagine placing a heavy tool close to a project by using the side of a toolbox, for example.

Why Magnetic Hooks Have Historically Not Been the Greatest Tool Storage Solution?

Traditional magnetic hooks offer limited vertical hanging force. Generally, a traditional magnetic hook measures pull force vs shear force when claiming it can hold 25-50 lbs.

For a traditional magnetic hook to have the magnetic force to hold a tool that weighs over 10 lbs would require two things:

1. Thick steel over ½ thick

2. A strong enough magnet that once placed on the steel surface, would not be able to be taken off without the use of a crowbar or damage to the surface.

The “Innovation” of Gator Magnetics Technology

Gator Magnetic Hooks introduced an innovative technology that is revolutionizing the value of magnetic storage and organization. This is due to greatly increased vertical holding force than what traditional magnetic hooks can provide. Now, the heaviest power tools can hold securely on thin steel surfaces, while being able to easily remove and shift to new positions.

Shear Force vs. Pull Force

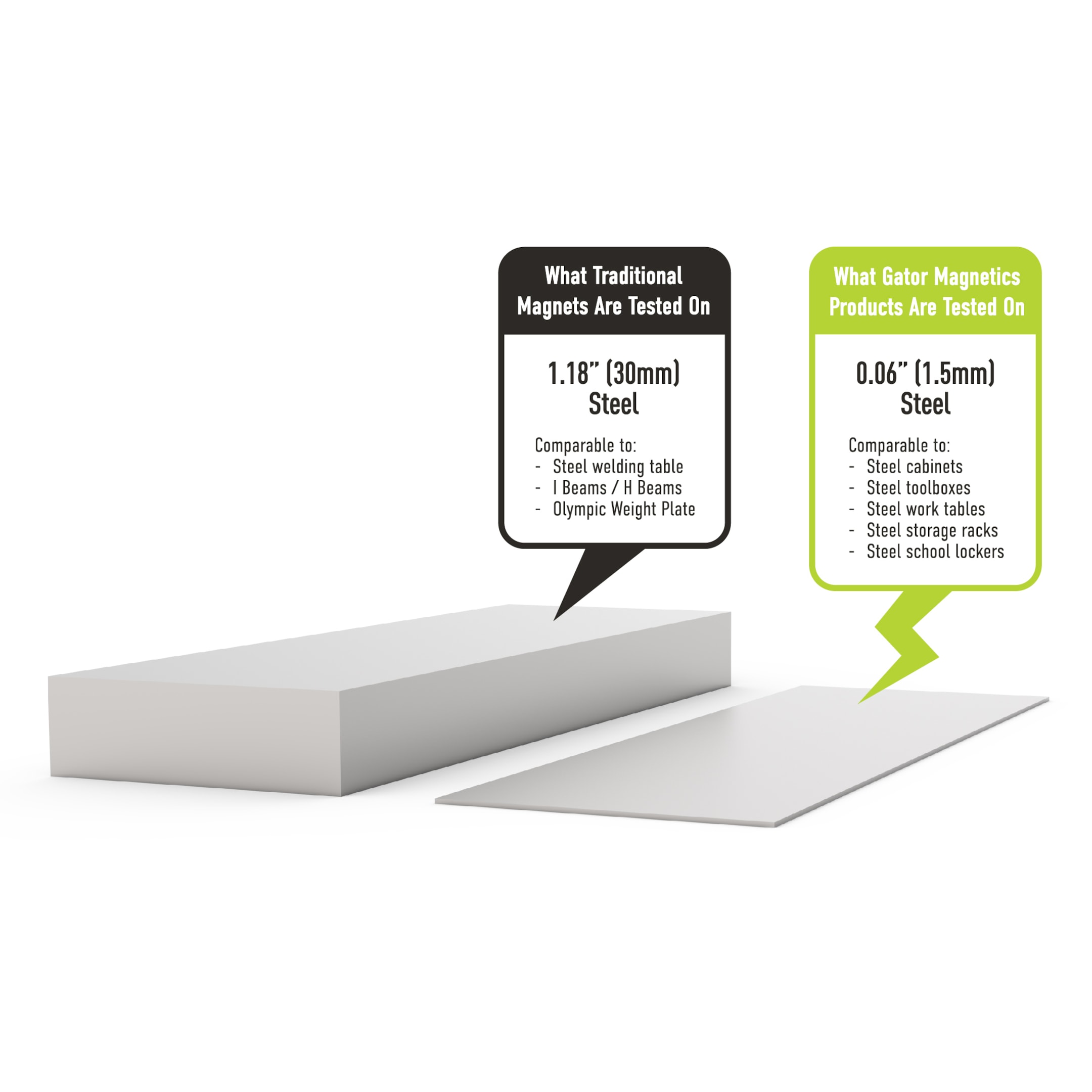

Other, traditional magnetic hook providers, typically advertise the holding force of the magnet by a straight pull on the magnet, perpendicular to the metal target that is 1/2" thick or more. However, this is not how magnetic hooks (or hooks in general) are used. They need to provide a vertical hold against the wall, tool cabinet, steel wall panel, or other sheet metal that is usually less than 1/2" thick. This can best be described as “shear force" hold on thin steel surfaces. Gator hooks are tested and measured by how much they can hold vertically (shear force towards the floor while securely holding on a vertical surface) and this is the only logical way to measure a hook because that is how they are used.

Thin Steel Surfaces.

Not only are the Gator Magnetics Hooks designed to hold on a steel vertical surface, but also to work on various gauge thinner steel surfaces commonly found in shops, garages, or homes. Traditional magnetic hooks are rated for pull force on thick steel at least 1/2" thick. This thickness in not often found in homes, garages, or workshops.

Gator Magnetics designed this system at the intersection of anthropometric weight limits and for holding the everyday light and heavy objects used in homes and workshops. The idea is simple, to make superior magnetic hooks, steel wall panel systems, magnetic baskets, and related products that are infinitely configurable. That is, set it up once, just the way you want it, or move the magnetic hooks whenever you need to for a project. It's that simple and effective.

The designs (including the magnetic patterns you don’t see without special tools) create the ability to take items of everyday use and put them visibly up on a wall holding system or on any one of many common sheet metal surfaces.

Common use items are often best managed in a reconfigurable wall hanging system:

1. We get items off the floor or work bench onto hooks and novel baskets and up onto the wall. This includes common items that were too heavy for magnetic hooks before our patented products came to the market.

2. For items of occasional use Gator products move things off the floor, out from under foot, and onto the wall. They can be positioned in a semi-permanent way or alternatively moved at will. The hooks are rated to carry weight with a safety factor, so you don’t need to worry about sudden dislodgement. Imagine placing a 7” Wet Tile Saw, that weighs 18 lbs. or a backpack gas blower that weighs 31.5 lbs, on a magnetic hook and holding it securely on a steel wall panel. That is unheard of. But with Gator Magnetics magnetic hooks that is exactly what they do.

What Do Tools Weigh

|

Power Tool Weight Chart (Avg) |

|

|

|

Description |

Lbs |

KG |

|

18V Cordless Drill |

10 |

4.5 |

|

Heavy Hammer Drill |

12.8 |

5.8 |

|

Angle Grinder |

11.2 |

5.1 |

|

Nail Gun |

2.6 |

1.2 |

|

Belt Sander (portable) |

7.7 |

3.5 |

|

Backpack Gas Blower |

31.5 |

14.2 |

|

7” Wet Tile Saw |

18 |

8.2 |

|

Weed Eater |

11.46 |

5.2 |

|

Reciprocating Saw |

7.1 |

3.2 |

|

Torque/Impact Wrench |

7.0 |

3.2 |

|

Heat Gun |

0.9 |

1.9 |

|

Oscillating Multi-Tool |

0.7 |

1.6 |

|

Screw Gun |

0.5 |

3.3 |

|

Circular Saw |

1.5 |

3.3 |

Contrasting Gator Hook Systems to Fixed Shelving and Hook Systems:

There are several types of storage systems generally available. There are fixed systems such as shelving systems, peg and hook systems, rail systems, and slat wall systems that combine shelving and hooking. Some of these systems make some flexibility available to the user when the system is set up such that it could be considered somewhat “configurable”. That is, if the user has a clear idea of how they want to prioritize the position of tools and other items, they will have the foresight to attach the permanent items and then position the “moveable fixtures. However, normally the repositioning of major items requires significant effort to reset the fixture (hooks and shelves). It may even require the user to entirely reset the system.

For obvious reasons, hooks sold as part of these systems are only purposed to function within those systems. They don’t function anywhere else. In contract, Gator Hooks can be taken anywhere and will provide important utility on most any steel surface. If the value of a hook is based on its utility, a hook that will function in a very wide variety of settings has superior value.

Why buy an accessory that requires another purchase just to be useful? A great product should stand on its own, not be dependent on something else to justify its value.

Magnetic hook systems that are on the market are inherently moveable and therefore configurable - but have a cardinal failure, that doesn’t hold weight. Typically hook systems rated at 25 lbs are rated at the “pull force” to remove the magnet from its target. But these ratings are not particularly useful in estimating how much the hook will hold in shear (vertical holding force as a hook.) Our experience is that hooks rated at 25 lbs holding force may only hold 5 lbs before slipping down a sheet metal surface. Gator Hooks are designed to hold 25 or 45 lbs (MIDI or MEGA) on most sheet metal surfaces, enough to hold almost any hand tool.

What’s Different about Gator Products:

Gator products are designed with patent protected methods to create unusual and specific magnetic flux patterns to meet specific applications that overcome the limitations of other magnets. They are much stronger, especially on thinner metal where there is almost no comparison in holding force.

Gator Products are a combination of magnetic clamping and friction forces such that the devices can provide stable hook locations for all sorts of tools and other common items - and they can do it in an infinitely reconfigurable system. Just remove the hook with a simple, one hand lever-lift and place it where you want it, to hold whatever you want. It is light force to lift the lever and easy to remove it. So even if you are reaching for a hook, the removal force is low enough to easily remove it and move it.

Imagine being able to make a specific tool handy for a specific task. Hang the tool you’re using right where you need it, on any sheet-metal surface, like your toolbox.

Organizing Your Workspace with Magnetic Storage

A well-organized workspace not only improves productivity but also reduces the risk of accidents. Here are some practical steps to implement magnetic storage systems in your garage or workshop:

Assess Your Tool Collection: Identify frequently used tools and group them by type.

Decide on Placement: Choose wall areas that offer easy reach and visibility for your tools.

Install Magnetic Panels and Racks: Securely mount these systems to your walls to create a compact and organized storage setup.

Store Tools Systematically: Hang or position tools based on usage frequency to enhance accessibility.

For detailed instructions on setting up magnetic panels, visit This Old House’s guide to tool organization.

For detailed instructions on installing Gator Magnetics Steel Wall Panels, visit https://youtu.be/6HH_9xXw9wQ

Tips for Storing Large Power Tools in Your Garage

Storing large power tools, such as table saws or miter saws, requires thoughtful planning to maintain a clutter-free space. Magnetic storage solutions can complement traditional methods, such as using racks and shelves, by offering additional options for accessories and smaller components.

Use Magnetic Holders for Accessories: Store saw blades, fasteners, and clamps within easy reach.

Combine Magnetic Panels and Shelves: Create a layered storage system for tools and materials.

Optimize Floor Space: Keep larger tools off the ground by using hooks or wall-mounted brackets.

Enhancing Durability and Security with Gator Magnetics

One of the standout features of Gator Magnetics’ products is their durability. Built with heavy-duty materials, these storage solutions can handle the weight of various tools without compromising security.

Durable magnets: Designed to withstand frequent usage and repositioning.

Secure grip: Prevents tools from slipping or falling, ensuring safety in the workspace.

Enhanced organization: Allows for easy access and reduces wear and tear on tools.

Common Mistakes to Avoid in Magnetic Storage

When using magnetic storage solutions for your power tools, there are several common mistakes to avoid. These mistakes can compromise the effectiveness and safety of your storage system and may even damage your tools.

Overloading: Avoid overloading your magnetic storage solution that exceeds the weight capacity of the magnetic holders. Traditional magnetic hooks have a very limited shear force weight capacity so this will likely be a problem. Gator Magnetics specializes in shear weight capacity to hold up to 45 lbs. When holding this much weight, ensure that you distribute the weight evenly. It is recommended to always test the magnetic holding power on new steel surfaces.

Incorrect Understanding of Holding claims: Make sure to install your magnetic storage solution correctly, following the manufacturer’s instructions. As previously stated, traditional magnetic hook manufacturers base their weight claims on pull force testing on thick steel and not shear force testing on thinner steel surfaces. That is why a traditional magnetic hook product may have "holds up to 50 lbs" listed on the packaging but when used to hold 5 lbs on a vertical steel surface, it will slide to the ground. Gator Magnetics holding claims are based on shear force testing, and on many different thin steel thicknesses to come up with their holding capacity claims of 15, 25, 35 and 45 lbs.

Inadequate Maintenance: Grease, grime and dirt can accumulate on steel surfaces. Regularly clean and maintain your steel surfaces to ensure that it remains effective and safe. This includes wiping down the magnets and storage surface with a soft cloth with an Isopropyl alcohol, to remove grease, grime and dirt. Regular maintenance helps maintain the strength of the magnets and the overall functionality of the storage system.

Incompatible Tools: Avoid storing tools that are not compatible with your magnetic storage solution. Some tools, because of their shape, may place too much shear weight on the tip of the hook and may limit the performance. If you're not sure of a tools weight, always check the shape compatibility of your tools with the Gator Magnetic hooks before use.

By considering these key features, understanding the different types of magnetic storage solutions, and avoiding common mistakes, you can create an efficient and safe storage system for your power tools.

Reviews and Testimonials

Customers consistently praise Gator Magnetics for their practical and reliable storage solutions. According to Garage Tool Reviews, “Gator Magnetics offers the best way to organize tools in a compact and efficient manner, making them a top choice for professionals and hobbyists.”

Conclusion

Magnetic storage solutions provide a practical and efficient way to organize your power tools, ensuring they remain easily accessible and in great condition. Gator Magnetics stands out as a leader in this space, offering a variety of products that cater to diverse storage needs. Whether you’re a DIY enthusiast or a professional, investing in magnetic storage systems can transform your workspace into a highly functional and organized area.

Safety Notes and Citations:

OSHA and CDC sites “awkward handling” for injuries with common tools, mostly involving a reaching arm, particularly if there is force required to initiate the move of the object and there is any angle of body or hand causing twisting. For more information see:

CDC Easy Ergonomics (Cal/OSHA, NIOSH) publication https://www.cdc.gov/niosh/docs/2004-164/default.html

NIOSH Lifting Equation https://stacks.cdc.gov/view/cdc/110725

NIOSH recommends repositioning work to eliminate a long/excessive reach and enable working in neutral postures. The recommended weight limit is 5kg for loads held at arm’s length and/or at above shoulder height. Repositioning a tool you commonly use may be important to avoid musculoskeletal injuries (injuries to the muscles, bones, joints, ligaments, tendons, and other soft tissues).

For more information see:

https://www.osha.gov/ergonomics

https://www.cdc.gov/niosh/ergonomics/index.html

https://injuryfacts.nsc.org/work/safety-topics/musculoskeletal-injuries/

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.