Choosing between magnetic hooks vs adhesive hooks depends on your needs for strength, surface type, and ease of use. This guide will help you decide which type of hook is best for your specific requirements.

Key Takeaways

Magnetic hooks are highly durable, versatile, and capable of supporting heavier weights, making them suitable for various environments, especially metal surfaces.

There are weight limitations for both regular neodymium magnetic and adhesive hooks.

New, revolutionary magnetic technology is changing the way magnetic hooks work and now provide a tremendous shear weight holding capacity making hanging heavier tools and items possible as never before.

Adhesive hooks are convenient for lightweight items on non-metal surfaces but have lower weight capacities and shorter lifespans due to adhesive degradation.

While magnetic hooks have a higher initial cost, they provide long-term savings through reusability, whereas adhesive hooks may seem affordable but incur ongoing replacement costs.

Understanding Magnetic Hooks

Magnetic hooks are designed to attach securely to metal surfaces, primarily ferromagnetic materials such as steel or iron. These hooks are known for their high weight capacity claims, making them a a choice for hanging heavier items. From a user experience perspective however, the regular magnetic hook weight capacity claims compared to how the magnetic hook actually performs, is inconsistent.

Strong Magnetic Hooks: The Magnetic Industry's Little Secret

When it comes to strength, magnetic hooks are unparalleled. Some strong magnetic hooks however, claim they are capable of supporting up to 50 pounds on thick metal surfaces, making them suitable for heavy-duty applications. So, why is it that a magnetic hook that claims on its packaging that it supports 50 lbs. will slide down a vertical steel surface as it fails to hold the weights claimed?

Most people, when they read 'Holds 50 lbs.,’ assume the hook can easily hold 50 lbs in the way they'd naturally hang things—on a vertical surface. But the truth is, those weight claims refer to a very different measurement.

The answer can be found on the back of the packaging in small print: Holding strength is measured by pull strength on thick steel surfaces. When magnetic hook weight capacity claims are made for a regular neodymium magnetic hook, they are touting pull force weight, which means the amount of force it takes to pull the magnet directly off at least a ½” thick steel surface.

There are several major challenges with this little known fact:

1.An overhead ½” thick steel beam is seldom found in homes or accessible in garages or workshops. Most available steel surfaces will be thin steel, found on steel doors, steel cabinets, tool boxes, racks or steel walls.

2. For a hook to function properly to hang an item, we generally want it to hang on a vertical surface, perpendicular to the floor, at a right angle, not vertically from above.

3. When a regular neodymium magnetic hook has claims it holds 45 lbs. of pull force, that will often be equal to less than a 9 lb. capacity for its shear force which is explained in more detail below.

What is the resulting general consumer consensus to this fact? A perception that magnetic hooks don’t work as a hook should to hang heavier items.

There is a new, revolutionary magnetic technology that has changed how magnetic hooks work.

Instead of measuring pull force on thick steel surfaces, there is a new patented magnetic technology from this company; Gator Magnetics, that measures shear force on thin steel surfaces. Shear force is the amount of weight the hook can hold in a downward direction, towards the floor.

Gator Magnetics uses their patented “Maxel” technology and easy release lever system that is designed and optimized to provide incredible shear force holding power of their magnetic utility hooks and baskets. This results in unheard of gripping strength that can now be used to hold the heaviest of items…up to 45 lbs. of shear force on thin steel surfaces.

With Gator Magnetics, you don’t have to worry about checking for thick steel beams or positioning the hook perfectly to make it work. The Maxel technology is designed to work on everyday surfaces like the steel doors, cabinets and toolboxes you actually have.

Science Meets Magnetic Hooks

Traditional neodymium magnets have north and south poles on opposite sides of the magnet creating a large looping magnetic field that loses energy and is inefficient.

The Gator Magnetics technology programs north and south pole dots, called “Maxels” in specifically designed and proprietary patterns creating many shorter magnetic fields that interact, engage, and grip, with incredible load capacities to thin steel surfaces. All this make the Gator magnet "hook system" much more efficient to adhere to common thin steel surfaces found in homes and garages and creates an exponentially stronger shear force than traditional magnets.

All of Gator Magnetics patented components: the chassis, the programmed magnet and pattern of Maxels, the hook, and the easy release lever mechanism, all function together, delivering its shear force gripping power. A Gator Magnetic Hook can be easily moved repeatedly with no damage to the steel surface it's on.

Why Magnetic Shear force vs. Pull Force Matters.

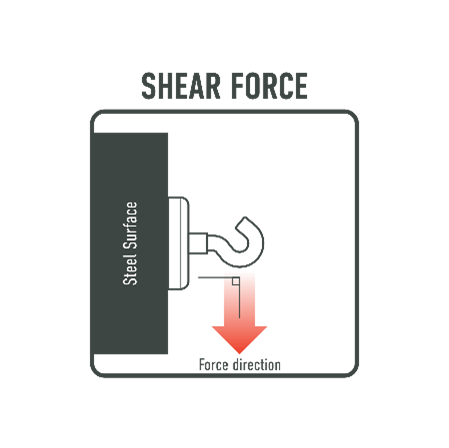

To equate pull force to shear force for a magnetic hook, we need to understand that pull force and shear force are two different ways of measuring a magnet’s holding power:

Pull force is the force required to pull the magnet directly away from a steel surface (perpendicular force).

Shear force is the force required to slide the magnet across or downward on the steel surface.

Key Factors:

Pull Force: The maximum load the magnet can hold in a straight vertical direction, i.e., lifting weight directly off the steel.

Shear Force: The force it takes to slide the magnet downward on a steel surface.

There isn't a simple universal formula to directly convert pull force to shear force because the ratio depends on various factors, including:

Friction coefficient between the magnet and the steel surface.

Surface smoothness and thickness of the steel.

Geometry of the contact area.

It is because the industry measures pull force, not shear force, is why a magnetic hook may claim to hold 45 lbs. vertically but may only hold less than 9 lbs. when force is applied downward.

Versatility of Magnetic Hooks

Magnetic hooks are extremely versatile, suitable for a wide range of environments, from homes and offices to industrial settings. They are particularly useful for organizing spaces by hanging tools, kitchen utensils, and even artwork. This versatility makes them a valuable addition to any space where organization and efficiency are priorities.

Whether you need to hang items in your garage, kitchen, or office, magnetic hooks offer a reliable and reusable solution. They can be easily repositioned without causing damage, adding to their practicality and appeal.

Today, by using a Gator Magnetics Hook, the limitations or concerns about hanging your heaviest items or tools without sliding down a steel surface are gone.

Exploring Adhesive Hooks

Adhesive hooks provide a versatile solution for non-metal surfaces like walls, tiles, or glass. They’re a go-to for quick, lightweight hanging solutions, but when compared to magnetic hooks, they fall short in terms of durability and weight capacity.

Advantages of Adhesive Hooks:

Versatility: Can be used on almost any smooth, non-metal surface.

Lightweight Champions: Ideal for hanging keys, small picture frames, or decorations.

No Tools Required: Installation is simple, requiring no screws or nails.

However, adhesive hooks have limitations, particularly when it comes to consistently holding heavier items. Environmental factors like humidity can degrade the adhesive over time, leading to unexpected failures.

Surface Sensitivity

Adhesive hooks work best on smooth, clean surfaces. Their holding power diminishes on rough or uneven walls, and on porous materials, they might not adhere well at all. While practical for short-term or lightweight hanging needs, adhesive hooks lack the longevity and reliability of magnetic hooks.

Comparing Weight Capacities

Magnetic Hooks: Heavy-Duty Power

Gator Magnetics hooks outperform adhesive hooks by a wide margin, supporting up to 45 lbs. of shear force on thin steel surfaces. Regular neodymium magnetic hooks claim higher weight capacities but are limited when used on thinner or vertically aligned surfaces.

Adhesive Hooks: Lightweight and Limited

Most adhesive hooks can hold between 1 and 5 lbs., with some heavy-duty versions supporting up to 20 lbs. However, adhesive degradation can cause these hooks to lose their grip over time, especially when exposed to humidity or temperature changes. This makes adhesive hooks less suitable for heavy or valuable items that require secure hanging. It is important to consider these limitations when choosing adhesive hooks for your hanging needs.

Adhesive hooks are also stationary. In order for these hooks to be moved requires they be removed, purchase more adhesive strips, and go through the steps to adhere to the wall again.

Installation and Removal

Magnetic hooks are incredibly easy to install—just slap them on a metal surface. No drilling, no mess, and no surface damage. Plus, they’re reusable and can be repositioned as needed without leaving behind residue.

Adhesive hooks, on the other hand, require more prep. Surfaces must be clean and dry, and removing these hooks can leave behind sticky residue or even peel paint or wallpaper. Magnetic hooks, especially those from Gator Magnetics, eliminate these hassles entirely.

Durability and Longevity

Magnetic Hooks: Built to Last

Magnetic hooks retain their holding power indefinitely. Gator Magnetics hooks feature neodymium magnets, which are corrosion-resistant and retain their magnetic strength for years, making them a durable option for long-term use.

Adhesive Hooks: Shorter Lifespan

Adhesive hooks degrade over time due to adhesive wear, particularly in humid or heat-prone environments. This short lifespan means more frequent replacements, which adds to the cost over time.

Best Use Cases

Magnetic Hooks

Ideal for heavy-duty applications in garages, workshops, or industrial settings. Gator Magnetics hooks are perfect for hanging heavy tools, vacuum cleaners, or lawn chairs and ladders, thanks to their high shear strength and ease of use.

Adhesive Hooks

These are best suited for quick and lightweight hanging needs on non-metal surfaces. They work well for hanging picture frames, decorations, or small household items, especially in rental spaces where drilling isn’t allowed.

Magnetic Hook Precautions

Handling powerful magnets requires care to avoid pinching fingers or trapping hands. When packing magnetic hooks for travels, it is advised to keep them away from electronic devices to prevent damage. These precautions are necessary to maintain safety and ensure the magnets do not interfere with sensitive equipment.

Additionally, individuals should be aware of the strong magnetic fields generated by these hooks, which can potentially disrupt electronic devices and medical equipment. Proper storage and handling techniques can mitigate these risks, making magnetic hooks a safe and effective solution for various applications.

For a regular neodymium magnetic hook to have the power to hold 20, or 60 lbs. of shear force, it would be very difficult for a user to place, move, or remove the hook from the steel surface by hand without damaging themselves or the surface.

Gator Magnetics has solved these issues.

No more pinched fingers because the patented short magnetic field created by Gator’s technology is much more controlled. Their unique lever system makes it easy to remove and place wherever you need to hang an item on a steel surface. In addition, Gator’s products have no effect on electronics or medical equipment.

Adhesive Hook Cautions

Improper installation of adhesive hooks can lead to surface damage, necessitating careful preparation before application. Ensuring the surface is clean, dry, and free of dust or debris is crucial for proper adhesion. Careful surface preparation can help to avoid accidents and ensure better adhesion of adhesive hooks.

Correct installation techniques are essential for preventing damage when using adhesive hooks. Following manufacturer guidelines and taking the necessary precautions can ensure the safe and effective use of adhesive hooks, preventing potential issues such as peeling paint or wallpaper.

Adhesive hooks present fewer safety risks, but improper installation can lead to heavy items falling, potentially causing injuries.

Cost Analysis

Magnetic hooks come with a higher upfront cost but offer better long-term savings due to their durability and reusability. In contrast, adhesive hooks are cheaper initially but can become costly over time due to their need for frequent replacements.

Magnetic Hooks: Higher Initial Cost, Long-Term Savings

Magnetic hooks come with a higher upfront cost compared to adhesive hooks. However, they provide better value over time due to their reusability and durability. A single magnetic hook can last for many years, making them a cost-effective solution in the long term.

Their efficiency and long lifespan lead to significant savings over time, outweighing the higher initial investment. For individuals and businesses looking for a durable and reliable hanging solution, magnetic hooks are a worthwhile investment.

Adhesive Hooks: Affordable but Frequent Replacement

Adhesive hooks tend to have a lower initial cost. This makes them appealing to consumers who are mindful of their budget. However, their need for regular replacement can lead to increased costs over time. The lower initial cost of adhesive hooks can be misleading, as the frequent replacements make them more expensive in the long run.

Considering the cumulative costs of replacing adhesive hooks, it is important to weigh the short-term savings against the long-term expenses. For temporary or lightweight hanging needs, adhesive hooks offer a quick and cost-effective solution, but for more permanent and heavy-duty applications, magnetic hooks may be the better choice.

Summary

In summary, both magnetic hooks and adhesive hooks offer unique advantages and challenges. Regular Magnetic hooks are known for weight capacity measuring pull force, durability, and ease of installation, making them ideal for lighter-duty and long-term applications.

Gator Magnetics however, is the revolutionary magnetic technology that measures shear force holding power, and therefore can provide the magnetic holding grip for all your heaviest tools and hangable items on thin steel surfaces.

Ultimately, the choice between magnetic and adhesive hooks depends on the specific needs and environment. By understanding the features, installation processes, durability, use cases, safety considerations, and costs of each type, you can make an informed decision that best suits your hanging needs.

Frequently Asked Questions

Can magnetic hooks be used on any surface?

Magnetic hooks are only effective on ferromagnetic surfaces like steel or iron and cannot be used on non-metal surfaces such as wood or plaster.

How much weight can strong magnetic hooks support?

Strong magnetic hooks can support pull force weights of up to 50 pounds on thick metal surfaces and up to 160 pounds on thick steel surfaces.

Gator Magnetics Hooks can hold up to 45 lbs. of shear force on thin steel surfaces, making them highly effective for various hanging needs.

Are adhesive hooks reusable?

Adhesive hooks are generally not reusable, as they are designed for one-time use and may leave residue or damage the surface upon removal. It's best to consider alternatives if you need a hook that can be reused multiple times.

What precautions should be taken when using powerful magnetic hooks?

When using powerful magnetic hooks, it's essential to handle them carefully to avoid injury and keep them away from electronic devices to prevent damage. Additionally, individuals with pacemakers should exercise caution when using these magnets.

This is not true when using Gator Magnetics Hooks. Because of their short magnetic field, there is no effect on electronic or medical devices.

Why do adhesive hooks need frequent replacement?

Adhesive hooks require frequent replacement because they can lose their holding power due to adhesive degradation, particularly in humid or variable temperature conditions. This results in a diminished lifespan necessitating regular updates.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.